Why “Nominal from Part” Is a Critical Mistake in CMM Programming

In 3D metrology, one of the most common — and most dangerous — shortcuts is creating nominal geometry directly from a real part.

This technique, often called “nominal from part,” may seem simple and fast, but it can completely compromise measurement accuracy, repeatability, and compliance with ISO GPS and GD&T requirements.

In this article, you’ll learn:

-

what “nominal from part” means

-

why it is risky

-

how it affects measurement and production

-

what ISO/ASME standards require

-

what you should do instead

What Does “Nominal from Part” Mean?

“Nominal from part” means creating planes, lines, circles, or datums by clicking directly on the surfaces of a real component, instead of using:

-

the CAD model

-

the technical drawing

-

GD&T definitions

-

ISO 1101 / ISO 5459 / ISO 8015 rules

It may look like a time-saving shortcut, but it introduces significant measurement errors.

1️⃣ Your Program Becomes Valid for Only One Part

If you create nominal geometry from a real part, your CMM program becomes dependent on the shape and manufacturing errors of that specific component.

The next parts will have:

-

different inclinations

-

different curvature

-

different machining deviations

-

different deformations

➡ Result: inconsistent and non-repeatable measurements.

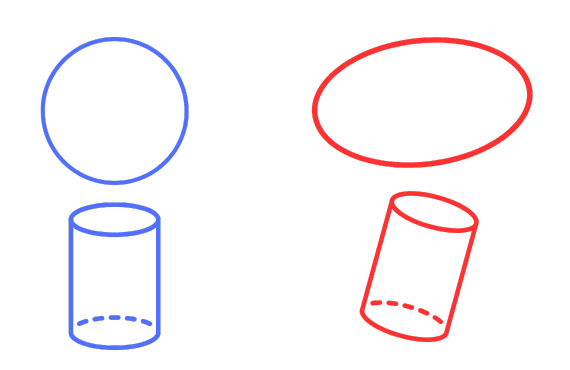

2️⃣ Manufacturing Errors Become Your “Design Intent”

This is the most dangerous outcome.

If the surface of the part is:

-

tilted

-

deformed

-

warped

-

shifted

…all these defects become the “reference geometry” in your CMM program.

You no longer measure parts against the drawing —

you measure them against the defects of the part used during programming.

This contradicts ISO GPS and ASME GD&T at a fundamental level.

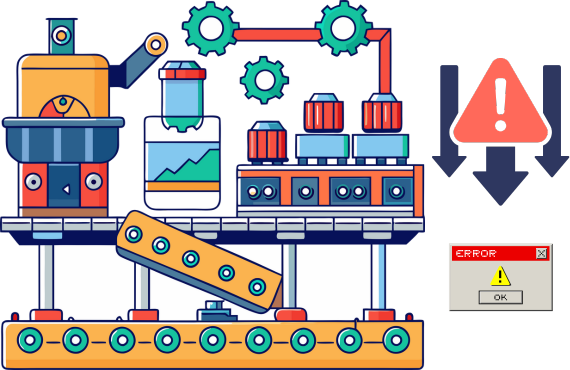

3️⃣ Circles Become Ellipses and Geometry Is Corrupted

If the nominal plane or surface is incorrect:

-

reconstruction vectors are wrong

-

circles are measured as ellipses

-

axes shift

-

position tolerances become unreliable

-

you get false NOK or false OK results

This directly affects the quality and credibility of the measurement report.

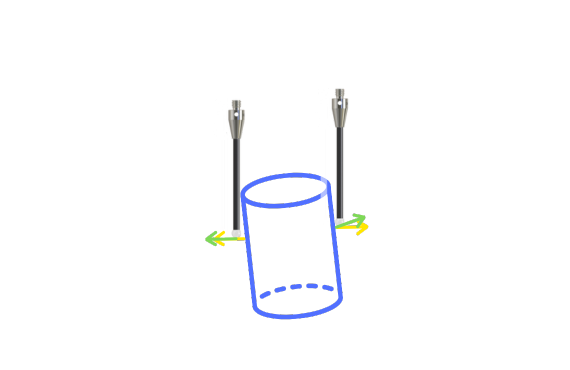

4️⃣ Collisions and Path Errors Increase

Incorrect nominals lead to:

-

wrong approach vectors

-

probe collisions

-

unstable path generation

-

missing points

-

unpredictable movements

A robust CMM program needs stable, standard-based nominal geometry.

5️⃣ Total Loss of Traceability — Major Risk in Audits

Audits such as:

-

IATF 16949

-

PPAP

-

VDA 6.5

-

customer audits

require proof of:

-

what was measured

-

what datum system was used

-

which GD&T definitions apply

-

alignment with ISO 8015 and ISO 1101

With nominal-from-part, you cannot prove any of these.

It is considered a major non-conformity.

What You MUST Do Instead

✔ Always use the CAD model or the drawing

This is the only correct source of nominal geometry.

✔ Follow ISO 5459 for datum definition

Datums must not be created from real parts.

✔ Use proper alignment strategies

-

RPS alignment

-

ISO-based datum systems

-

Best-fit (when allowed)

-

Constrained alignments for flexible parts (ISO 10579)

✔ If CAD is missing — request it

Never program a CMM based only on real parts.

Conclusion

A real part is for measurement, not for defining geometry.

Nominal-from-part is a risky practice that compromises:

-

repeatability

-

accuracy

-

program stability

-

traceability

-

ISO/ASME compliance

If you want professional, consistent, and audit-proof measurement:

Nominals must come from the drawing. Always.